So almost a month has gone by since my last post. I've been busy and progress has been slow. I didn't see much point in doing any updates if I didn't have anything to add.

But now I do.

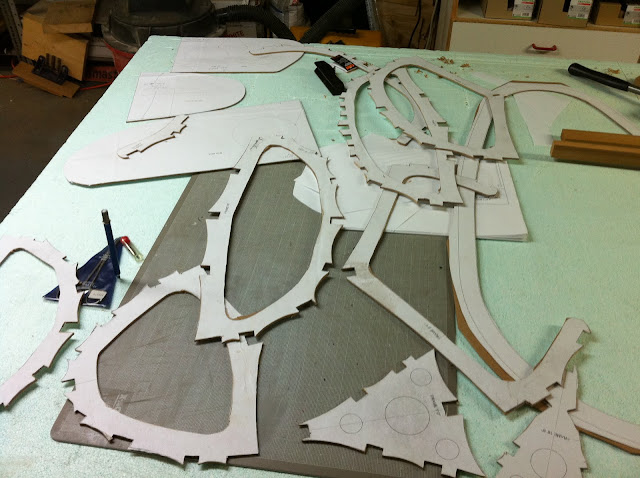

I finally got all the frames cut, properly sized, and rounded.

My original idea of using a router to cut them didn't work out. My templates were too thin (1/8") and I couldn't get the bearing on the bit to properly follow the template. So I ended up using the templates as patterns and cut all of these out with my jigsaw.

Know what this is?

Yup. That's blood alright. But not mine. My friend Sam was over this weekend and decided he wanted to come downstairs and give me a hand. So I gave him some chisels and asked him to start cutting out the notches. I guess my chisels are a little sharper than what he is use to. That WorkSharp 3000 is really doing a great job keeping my chisels and planes "scary sharp". I love it.

I also managed to get my strongback started.

The kayak will be built on this. Some people build very fancy strongbacks, and I may do that one day, but for the moment, the only thing I intend to do is put some 1/2" plywood down the length of it so I have something smooth to work on.

Here's the same pic with the frames laid out.

Does it look like a kayak yet? :) I suppose not. But I'm getting there.

Finally, a little more gloating. My Festool collection is coming along nicely. I really like the way all the containers stack together.

Next I will be oiling all the stringers and frames before I start the assembly.

So, progress is being made!

And I'm having a very good time.

But now I do.

I finally got all the frames cut, properly sized, and rounded.

My original idea of using a router to cut them didn't work out. My templates were too thin (1/8") and I couldn't get the bearing on the bit to properly follow the template. So I ended up using the templates as patterns and cut all of these out with my jigsaw.

Know what this is?

Yup. That's blood alright. But not mine. My friend Sam was over this weekend and decided he wanted to come downstairs and give me a hand. So I gave him some chisels and asked him to start cutting out the notches. I guess my chisels are a little sharper than what he is use to. That WorkSharp 3000 is really doing a great job keeping my chisels and planes "scary sharp". I love it.

I also managed to get my strongback started.

The kayak will be built on this. Some people build very fancy strongbacks, and I may do that one day, but for the moment, the only thing I intend to do is put some 1/2" plywood down the length of it so I have something smooth to work on.

Here's the same pic with the frames laid out.

Does it look like a kayak yet? :) I suppose not. But I'm getting there.

Finally, a little more gloating. My Festool collection is coming along nicely. I really like the way all the containers stack together.

Next I will be oiling all the stringers and frames before I start the assembly.

So, progress is being made!

And I'm having a very good time.